Hotline

+86-13692841862

Email:info@mayflay.com

Add::NO.289,Guangreng Rd,Xiaojinkou Str.Huicheng Dis,Huizhou City,Guangdong Province,China.

Surface Treatment Equipment

Coil Handling Equipment

Solutions

Application

About us

welcome to MAYFLAY

For consultation/feedback, please call the service hotline: +86-13692841862 Email:info@mayflay.com

The spinner hanger type shot blaster is almost an all-around machine for many types of work pieces surface treatment.

It is compact in design, does not require a pit(generally), and consists of units featuring single hook, double hooks, lifting and non-lifting style designed to blast/peen castings, structural components, non-ferrous alloy parts. Hanger type machines are the most flexible machine types, one batch of parts move in, starts rotating, gets blasted and moves out, are used for demanding and decoring of pieces susceptible to breakage or impact damage and also for descaling and reconditioning in the metalworking industry. This kind of machine includes a wide range of facilities whose main characteristic is the great variety of part sizes and loading configurations that are available.

Treated objects are hanged individually or in a cluster on the revolving hook and transported to the shot blasting machine via I, Y or circular closed loop conveyor. Revolving of treated objects in a jet of abrasive provides efficient treatment of the parts surface.

Spinner hanger shot blasting machine is typically designed to handle mixed loads of medium and large components, which often include fragile and sensitive parts that cannot be tumbled in bulk loads. Mayflay Spinner hanger shot blasting machines are ideal for heavy and complex shaped workpieces. Parts can weight from 1 kg to 3,000 kg or more, manufactured in smaller and medium series.

The Mayflay spinner hanger shot blasting machines are highly flexible systems that can be applied in many applications such as de-scaling, de-sanding, rust removal, paint stripping all fields of surface blast cleaning in the fields of steel structure, tank product parts, perforated parts, vehicle stabilizer bar, gear parts, transmission shaft, gear ring, forgings and castings etc.

It has its core advantages that make it excellent:

1. Blasting sealing: Special seals in the ceiling prevent blast materials spillage and reduce the noise level around the machine. A unique special multi-layer sealing system is developed and installed. It combines with brush seals and rubber segments to keep the machine nearly 100% tight when the hooks and cross bar are adapted to the sealing system and it prevents accidents of shot spillage.

2. Blasting machine body: 6mm thickness Manganese 13 steel plates welled welded in one piece and Manganese 13 steel protective boards, offering excellent wear resistance.

3. The basic separator is air-flow separator. Good shots are heavy and not driven to move by the air flow but broken shots are much lighter to be lead to the other slide board that connected with a broken shot collector/bucket. Dust directly flows in the air flow direction and is taken to the air exit to be dealt with by the dust collector. Multi-level plates are installed to adjust and balance the sliding shot flow amount. Good shots are collected by the shots storage cabinet for recycling usage.

4. Magnetic separator is available for powerful sand separating.

5. Semi-automatic flow valves: control the flow amount of the shots into the blast wheels with manual operation of adjusting the shots flow.

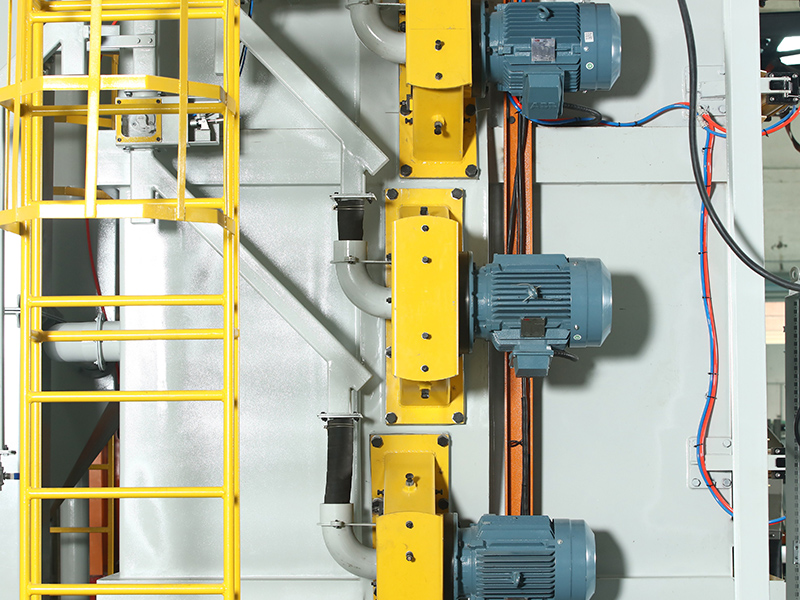

6. Our quality-guaranteed casted blasting wheel or even higher level all-CNC-machined blasting wheel provides excellent blasting result in very short cycle time.

7. Ultimately compact and smart design and small floor space occupation.

8. Programmable Logic Control. Safe operation, easy maintenance.

9. Maintenance and examination windows: windows are set on each maintenance position for easy maintenance.

10. Machine invisible appearance: all our machines are dealt with surface treatment with our shot blasting machine before they are painted. With our shot blasting machine treatment, the machine surface is excellent for painting. We use high-end vehicle oil paint for our machine to have high level of painting quality and you don’t need to worry about broken painting problem under extremely nasty working environment.