Hotline

+86-13692841862

Email:info@mayflay.com

Add::NO.289,Guangreng Rd,Xiaojinkou Str.Huicheng Dis,Huizhou City,Guangdong Province,China.

Surface Treatment Equipment

Coil Handling Equipment

Solutions

Application

About us

welcome to MAYFLAY

For consultation/feedback, please call the service hotline: +86-13692841862 Email:info@mayflay.com

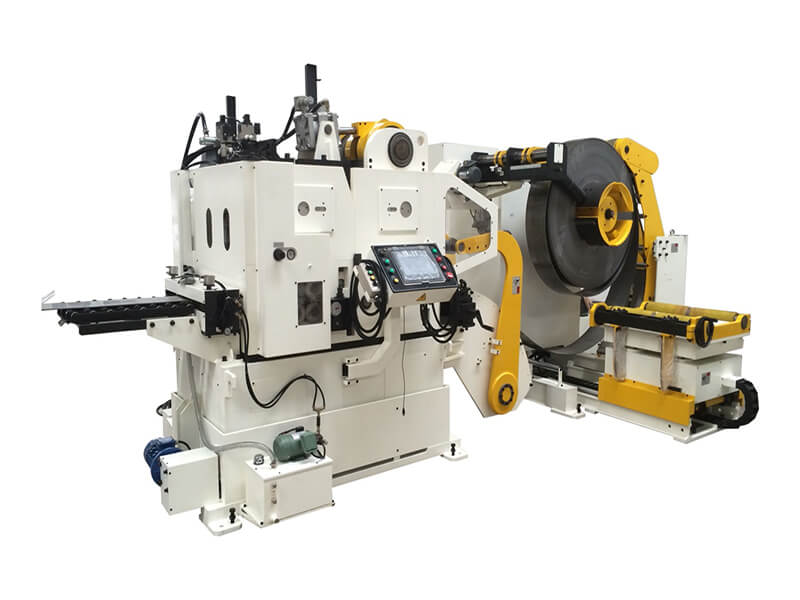

Advantages of three-in-one feeder

1. The three-in-one feeder has the advantages of easy operation. So why do you say that the feeder has such advantages? That is because the feeder is an automatic feeding device that integrates three kinds of machines: the material rack, the leveler and the feeder. The control knobs and switches of the entire equipment are uniform. Centralized in the console, staff can control the overall situation without having to go back and forth. The feeder adopts high-tech and high-efficiency operation methods. Among all the punching equipment, the three-in-one punch feeder can be said to be the top performance modification. The feeder can be said to be an advanced automatic feeding device in the industry.

2. The three-in-one feeder also has the advantage of easy installation. According to different needs, the three-in-one feeder is usually divided into 3 parts. The connection of the 3 parts is very simple and fast. It can be fixed with screws, which greatly reduces The time spent on installation quickly enters the state of production, and the three-in-one type after installation is also small, which greatly saves the area occupied by the plant, so that the plant can accommodate more equipment, reduce plant rental costs, and maximize benefits .

3. The three-in-one feeder has a wider range of applications. It can process thick plates and high-strength metal thick plates that cannot be processed by the split stamping production line. It is suitable for feeding and correcting various gold sheets. As long as the split press production line is suitable for thin plate and medium plate materials below 4.mm, once the thickness is thick and the material rigidity is large, it cannot be used for processing and production. Many customers can only use purchased sheets and manual The feeding method is used for stamping production, and the emergence of the stamping three-in-one feeder fundamentally solves this processing problem. The maximum thickness of the same serving material can reach 8mm, and it can be applied to the processing and production of various high-strength plates. The processing and production of thick plate materials can also be automated.

4. The three-in-one feeder also has the advantage of high precision. The split stamping production line composed of a single material rack, a servo machine, and a feeder is a completely separate three equipment, and there is a waiting area between each equipment, which makes it even if each equipment is equipped with a frequency conversion The operation and matching of the machine cannot be completely synchronized. In the end, it will more or less affect the accuracy of the servo and feeding. The punching three-in-one feeder integrates the rack, servo, and feeding into one machine, making the machine The collocation achieves complete synchronization, and the control of the PLC closed-loop system truly ensures the accuracy of servo feeding.

5. The three-in-one feeder adopts imported core components, a complete lubrication system, and a self-checking program with very low failure rate. The overall core components of the stamping three-in-one feeder are imported from Germany and Japan, such as Japan’s Yaskawa servo motor and driver, Sanxiu PLC, Omron Optoelectronics, Schneider circuit breakers, Japan NSK bearings, etc., and perfect lubrication. The system and its own self-checking program make the whole machine wear very little, the failure rate is very low, and the maintenance is very simple.