Hotline

+86-13692841862

Email:info@mayflay.com

Add::NO.289,Guangreng Rd,Xiaojinkou Str.Huicheng Dis,Huizhou City,Guangdong Province,China.

Surface Treatment Equipment

Coil Handling Equipment

Solutions

Application

About us

welcome to MAYFLAY

For consultation/feedback, please call the service hotline: +86-13692841862 Email:info@mayflay.com

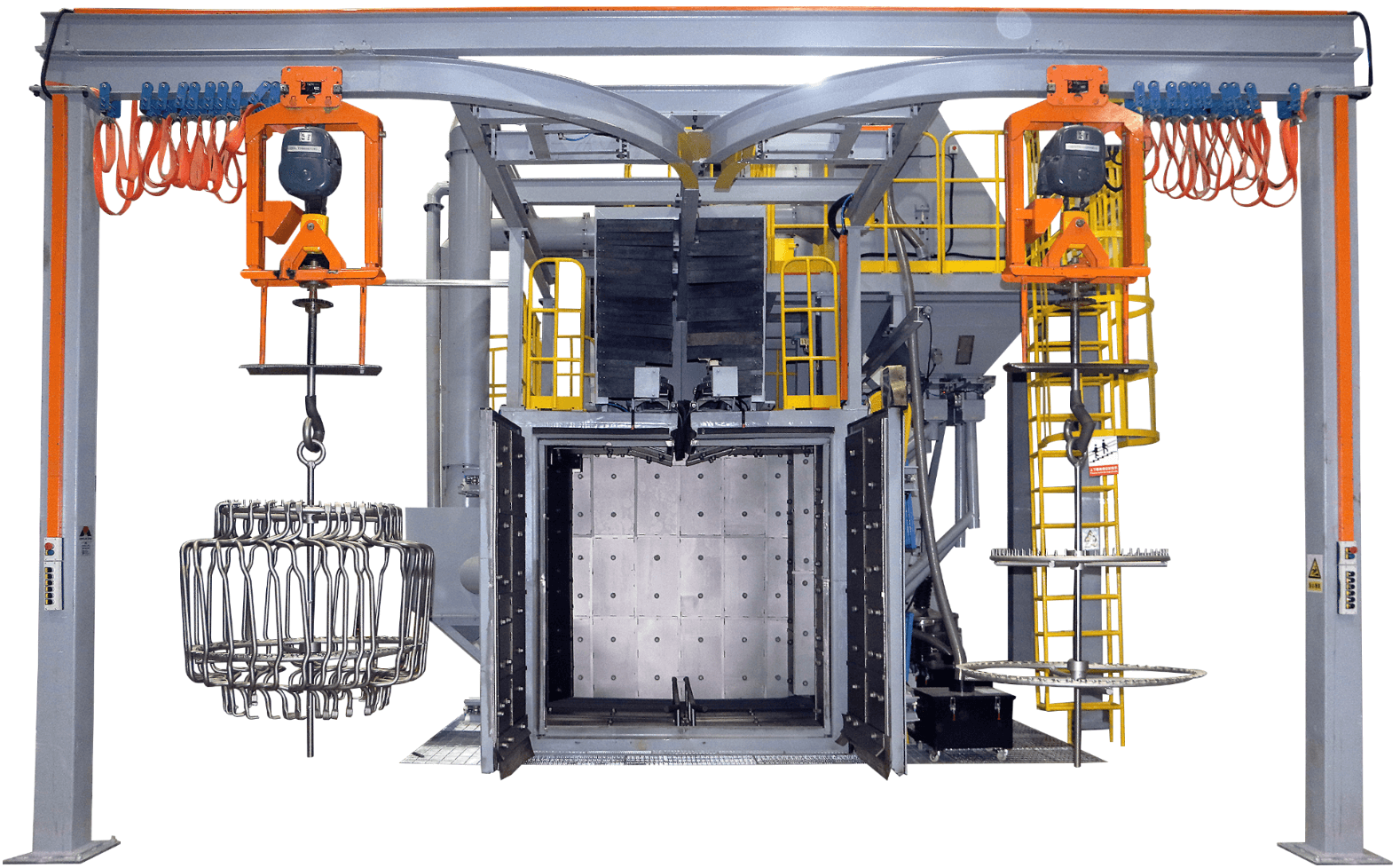

Shot blasting machines are now more and more widely used, but some machines are worn more seriously because they do not pay attention to daily maintenance and maintenance during use. After a period of use, the machine needs to be repaired due to serious wear and tear. Therefore, in order to ensure a long service life of the machine, the daily maintenance of the machine must be done well.

When using the shot blasting machine to clean the workpiece, in order to improve the working efficiency of the machine and reduce the wear of the guard plate during use, it is better to put more workpieces in the projectile area, but the workpiece cannot exceed The bearing capacity of the machine causes the machine to be damaged prematurely due to overloading. When installing the casting, the range of the casting must be within 300 to 500 kg. After the workpiece is added to the maximum range, in order to reduce the guard plate The degree of wear and tear of the machine will increase the service life of the machine. It is necessary to adjust the directional sleeve in the machine so that the iron shot thrown by the machine can be more thrown onto the workpiece to improve the working efficiency of the machine.

In order to ensure that the shot blasting machine can have a better service life, it is necessary to adjust the dust removal system in the machine at ordinary times and open the gates everywhere to make the air distribution more reasonable. This way A good dust removal effect can be achieved. A dust collector is often used to clean the dust of this machine to avoid jamming or blockage during the operation of the machine, which may cause premature damage to the machine.

Understand some common sense of daily maintenance of shot blasting machine, in the process of use, the degree of wear of the machine can be reduced, so that the machine can have a longer service life.