Hotline

+86-13692841862

Email:info@mayflay.com

Add::NO.289,Guangreng Rd,Xiaojinkou Str.Huicheng Dis,Huizhou City,Guangdong Province,China.

Surface Treatment Equipment

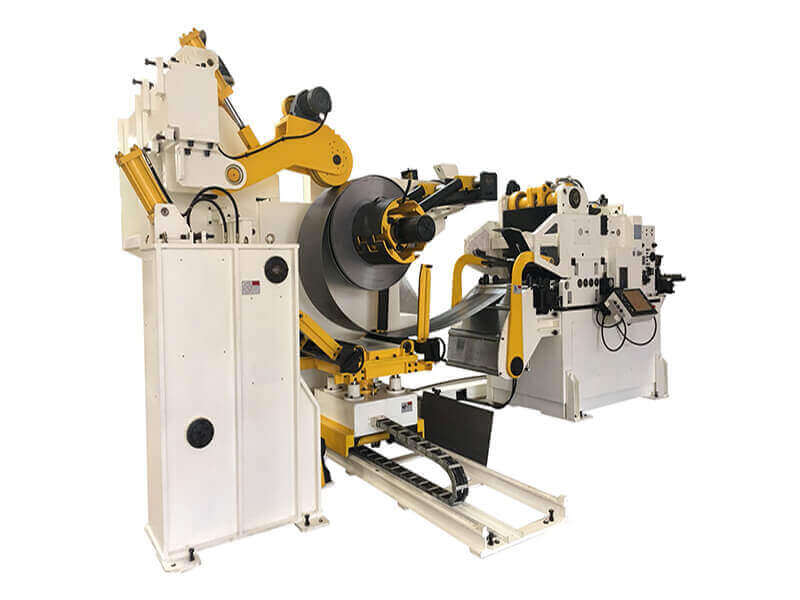

Coil Handling Equipment

Solutions

Application

About us

welcome to MAYFLAY

For consultation/feedback, please call the service hotline: +86-13692841862 Email:info@mayflay.com

Solutions to general failures under three-in-one leveling feeder

1. The relaxation device is not smooth

1. Check whether the positioning guide pin in the mold county is normal, carefully check and correct it.

2. The feeding direction is offset, check whether the working direction is correct and the mold is normal.

3. The eccentric shaft and the loose shaft are stuck due to loss of oil, use kerosene to clean and add butter.

2. Irregular feeding error

1. Check that the pressure on the apricot pressing plate is even, and adjust the pressure of the relaxation device.

2. If the feeding mechanism is pneumatically relaxed, check whether the air compressor pressure is normal.

3. Check whether the coil fed by the material rack is on the same level as the feeder and die.

3. Sudden errors occur during feeding

1. Whether the leveling machine is matched with the NC feeder, or whether the distance between the leveling machine and the feeder, the height of the material arc and the speed of the punching machine are appropriate.

2. Tighten the belt properly and check whether the length, width and thickness of the coil are standard.

The stamping industry is becoming more and more competitive, and how to choose equipment depends on the different circumstances of the company. Saving costs and improving production efficiency are the selection criteria of each enterprise. Three-in-one has excellent performance in all aspects. Choosing three-in-one will create higher benefits for the enterprise.