Hotline

+86-13692841862

Email:info@mayflay.com

Add::NO.289,Guangreng Rd,Xiaojinkou Str.Huicheng Dis,Huizhou City,Guangdong Province,China.

Surface Treatment Equipment

Coil Handling Equipment

Solutions

Application

About us

welcome to MAYFLAY

For consultation/feedback, please call the service hotline: +86-13692841862 Email:info@mayflay.com

The following are the precautions for the test machine of the hook type shot blasting machine.

First of all,before debugging the hook type shot blasting machine, be sure to check carefully whether the various parts of the machine are connected firmly, so as to avoid malfunctions during the operation of the machine and cause unnecessary trouble.

Secondly,at the beginning of the test run, test run without load for 2-3 hours. If there is no problem, open the hoist and screw conveyor, and add about 600Kg of new steel shot to the shot blasting machine from the door of the cleaning room. These projectiles are conveyed by the screw conveyor and lifted by the elevator, and stored in the hopper at the lower part of the separator.

After the operation, these projectiles will flow into the shot blasting device through the electric shot supply gate valve at the lower part of the hopper, and the workpieces to be cleaned in the cleaning room will be shot blasted.

Thirdly,when adjusting the shot blasting device, pay attention to the position of the directional sleeve of the shot blasting device so that the shots of the steel shot are all covered on the workpiece to be cleaned, otherwise the cleaning efficiency will be affected.

At last,start the shot blasting machine, and add a small amount of shots manually to the blasting pipe of the shot blasting machine. Check the position of the projectile belt. If the position of the projectile zone is incorrect, adjust the directional sleeve to obtain the ideal position. After the directional sleeve is adjusted, it can be tested under load. After 30 minutes of shot blasting, 400Kg steel shot can be added.

MAYFLAY is a high quality manufacturer of all types of surface preparation equipment and coil handling equipment.It has long been committed to the design and manufacture of shot blasting, shot peening, sandblasting and decoiler, straightener, feeder and press machine,and provides intelligent surface treatment solutions and sheet metal stamping solutions to customers around the world.

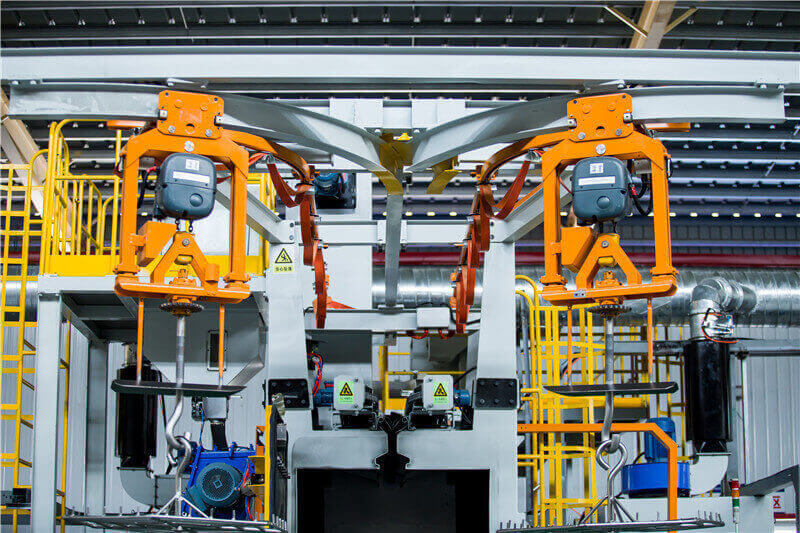

Spinner hanger shot blasting machine

Spinnger hanger shot blasting machine is suitable for surface cleaning or strengthening treatment of medium and small castings and forgings in gears, gear shafts, forging, casting, construction, chemical, motor, machine tools, etc., such as descaling, burrs, sand casting and sand removal.

Spinner hanger shot blasting machine is compact in design, does not require a pit(generally), and consists of units featuring single hook, double hooks, lifting and non-lifting style designed to blast/peen castings, structural components, non-ferrous alloy parts. Hanger type machines are the most flexible machine types, one batch of parts move in, starts rotating, gets blasted and moves out, are used for demanding and decoring of pieces susceptible to breakage or impact damage and also for descaling and reconditioning in the metalworking industry. This kind of machine includes a wide range of facilities whose main characteristic is the great variety of part sizes and loading configurations that are available.

Treated objects are hanged individually or in a cluster on the revolving hook and transported to the shot blasting machine via I, Y or circular closed loop conveyor. Revolving of treated objects in a jet of abrasive provides efficient treatment of the parts surface.

Spinner hanger shot blasting machine is typically designed to handle mixed loads of medium and large components, which often include fragile and sensitive parts that cannot be tumbled in bulk loads. Mayflay Spinner hanger shot blasting machines are ideal for heavy and complex shaped workpieces. Parts can weight from 1 kg to 3,000 kg or more, manufactured in smaller and medium series.

Application

1. Automotive industry

Engine blocks, cylinder heads, break drums, rear stabilizer etc.

2. Agriculture industry

Tractor components, water pumps, farm implements, etc.

3. Construction industry

Welded steel fabrications, Structural steel, transmission & television towers, etc.

4. Transportation industry

Engine blocks, axle & crank shafts, diesel engine components, etc.

5. Oil & gas industry

Pipes coating with paper, cement, epoxy, polythene, coal tar, etc.

6. Mining industry

Bulldozer, dumpers, crushers, land fill equipments, etc.

7. Foundry industry

Shot blasting: Automobile, tractor, scooter & motor cycle components, etc

8. Aviation industry

Jet engine, blades, propeller, turbine, hubs, land gear components, etc

9. Air polution control equipments

Foundry, carbon black, furnace, cupola, etc.

Features

Customizable machine size

This type machine is available in more design configurations and capacity sizes for low or high production parts requirements and also the size of the shot blast machine, and the number and power of the wheel blasters vary considerably depending on the parts to be blasted as well as on the expected result and efficiency.

Durability(Long Service Lives)

Shot blasting chamber is completely engineered from manganese steel plate with a thickness of between 6 and 10 mm. The blast chamber up to a certain models size is welded in one piece making the machines extremely tight and sturdy. For optimum wear protection, the area exposed to the blast stream is lined with replaceable protective plates constructed in manganese steel, these overlapping liners are not bolted on but hung with a special system.

High shot blasting efficiency

Our hanger shot blasting machine adopts the double hangers design, double-tracks, double-electric hoists conveying workpieces, can realize continuous shot blasting operation so that achieve high production efficiency.

Accurate blasting effect

To achieve complete coverage, the workpiece carrying hooks rotate and stop automatically at three different points in the blast cabinet. This rotation and process mean that even highly complex workpieces, with hard to reach surfaces, can be safely and accurately treated.

Easy to operate and maintain

Our machine adopts PLC control, all process parameters of products to be blasted can be set up and saved in program means that there is no need to repeat input, also with the characteristic of high degree of automation, high operation safety, low maintenance. Reducing labor input and improve the production efficiency.

Environmental Protection

Nowadays, as living standards and quality improve, noise and dust emission concentration are the two environmental issues that people are most concerned about. About our shot blasting machine, we have adopted advance methods to reduce noise to 85DB and dust emission concentration to less than 50mg/m3 ( if more strict requirements then needs high standard configuration which can be communicated).

Main Parts

Electric Hook And Rail System

a. Y type double rail input and output convey system, manual control loading and unloading, input and output conveyer.

b. 1 Set Y type rail system, 2 pcs working stations.

c. To achieve complete coverage, the workpiece carrying hooks rotate and stop automatically at three different points in the blast cabinet. This rotation and process mean that even highly complex workpieces, with hard to reach surfaces, can be safely and accurately treated.

Blast Wheel

a. Mayflay blast wheel studies Germany company TITAN series blast wheel.

b. The blast wheel is the heart of the blasting machine, as the choice of blast wheel determines the power output and the economics. This machine is fitted with titan shot blast wheels as standard.

c. Our CNC blast wheel offers excellent blasting performance and unbeatable service life for the main blast components, which are made from hardened tool steel can be optional.

Shot Blasting Chamber(Room)

a. A shot blasting room body made of 6mm manganese steel(Mn13).

b. In the shot blasting room protected with the plates made of manganese steel(Mn13), of thickness 10 mm.

c. Two doors covered with the wearing-out resistant rubber, opening/closing with pneumatic cylinders.

d. Trough made of manganese sheet metal and profiles covered with grids, preventing falling of larger pieces and thus breakage of the abrasive transport system.

Flow Control Valve

a. Flow control systems, used to control the steel shot flow into the shot blasting machine

b. Fully sealed structural design with lockable inspection window, equipped with two bearings

c. On the top of the each flow valve, in case that steel shots flowing from the storage silo, there is a manual stop valve been switched off when the flow valve needs to be repaired.

Separator System

a. To separate the steel shot, crushed steel shot and dust.

b. Welding structure, the internal a number well-designed rooms use for decided the wind direction. The front is an open access door for daily observation and maintenance.

c. Multipole adjustable plate structure is used to adjust the smoothness of the sand curtain.

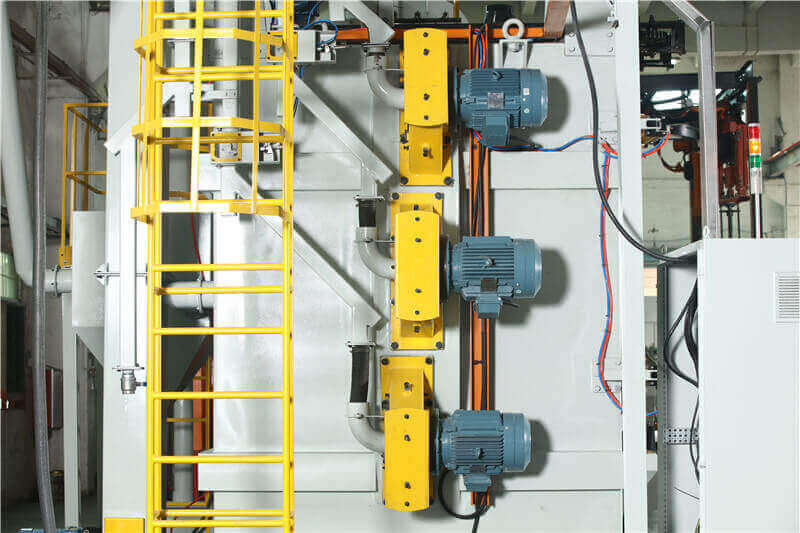

Screw Conveyor

a. Vertical spiral pusher, located at the bottom of the shot blasting chamber used to transport the abrasive up to the elevator bucket

b. Production process of the helix ensures that there are no micro fissures and micro tearing apart of the structure

Bucket Elevator

a. Rubber elevator belt.

b. Used to raise the shots recovered by the screw pusher to the sorting device and stock bin.

c. The system consists of 2 precise machined wheels, 1 elevator shell, 1 high-performance wear belt and a number of alloy lifting hoppers.

d. Doors for control and maintenance.

Magnetic Separator System(Optional)

a. The magnetic separator increases your profitability by reducing machine wear and reducing abrasive consumption.

b. Moulding and core sand on castings is removed during the blast process. As they cause high abrasion they must be separated from the ferro-magnetic abrasive quickly and efficiently.

c. Sand/abrasive mix passes through the rotary screen where the mix is metered onto the magnetic drum.

d. Abrasive passes under the magnetic separator drum, allowing sand and metallic fines flow to a trash container or transporter (by customer)

Electric Control Cabinet

a. PLC : Siemens

b. Frequency converter: Brand optional

c. Low voltage electrical components: Brand optional

d. 10 inches color touch screen

Filter Dust Collector

a. The internal filter is fast dismantling to facilitate the installation and replacement; A single cartridge dust area is 10m3.

b. The dust collector is with automatic back blow cleaning device,the time interval of back blowing can be set; and also with renewal instrument with the to indicate when the filter cartridge can be replaced.

c. Electronic regulation of length and blowing-out frequency