Hotline

+86-13692841862

Email:info@mayflay.com

Add::NO.289,Guangreng Rd,Xiaojinkou Str.Huicheng Dis,Huizhou City,Guangdong Province,China.

Surface Treatment Equipment

Coil Handling Equipment

Solutions

Application

About us

welcome to MAYFLAY

For consultation/feedback, please call the service hotline: +86-13692841862 Email:info@mayflay.com

The automatic feeder makes the operation more convenient.

Nowadays, the requirements for punch feeders in the field of stamping molds are getting higher and higher. High efficiency, high quality, high automation technology, and low common failures have long become the company's purchase rules, so the automation technology level of automatic feeders How big is it? Today, the latest NC servo feeder of Gelihao Machinery is developed and interpreted:

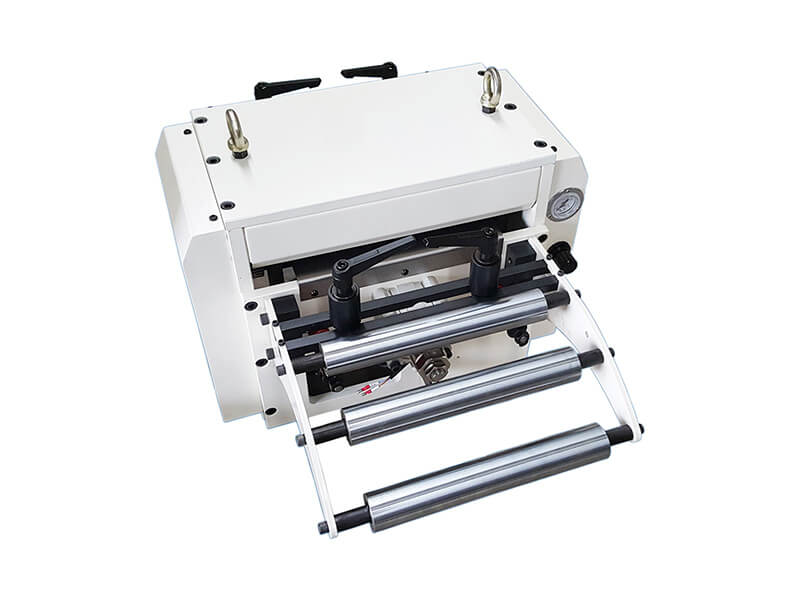

NC stock feeder, to put it bluntly, is a computer-controlled feeder, which is called a fully automatic feeder in the industry. So where is it fully automatic? First, let’s understand the composition of the machine and service equipment. The NC feeder is composed of a mechanical equipment engine and its electrical control cabinet. The engine is equipped with a servo motor and an electrical control cabinet. Including servo controller, PLC, industrial touch screen and other components.

The operation of the NC servo feeder is to install the plug-in after setting the feeding parameters, in the fully automatic mode, the PLC will send the differential signal set by the bending first to the servo motor drive and expose the equipment, and the drive operation commands the drive servo motor to develop the posture , And then achieve the purpose of feeding, the operator of Da Lian only has to set the relevant parameters, and the machinery and equipment can be produced and manufactured in one step without any control.

The industrial touch screen of the feeder and the replacement system software are also the key to whether the full automation technology can meet the expectations. Lihao's most NC servo feeder uses a 7-inch ultra-clear touch LCD screen from Taiwan, China, which can control the total The area is wide, the font style is clear. The reflection is dexterous, the operation setting parameters are visualized, and it has a storage function.

The touch screen adopts a replacement interface designed and made by Lihao, which can visually see various parameters of the system software. It is relatively simple to type and can be carried out in a short period of time. It can supervise the operation of the punch feeder anytime and anywhere. , Quickly inquire and set up, with the actual operating parameters, all functions are integrated on the operation panel, reducing complicated operations, providing customers with excellent human-computer interaction technology pages, simplifying on-site operations.