Hotline

+86-13692841862

Email:info@mayflay.com

Add::NO.289,Guangreng Rd,Xiaojinkou Str.Huicheng Dis,Huizhou City,Guangdong Province,China.

Surface Treatment Equipment

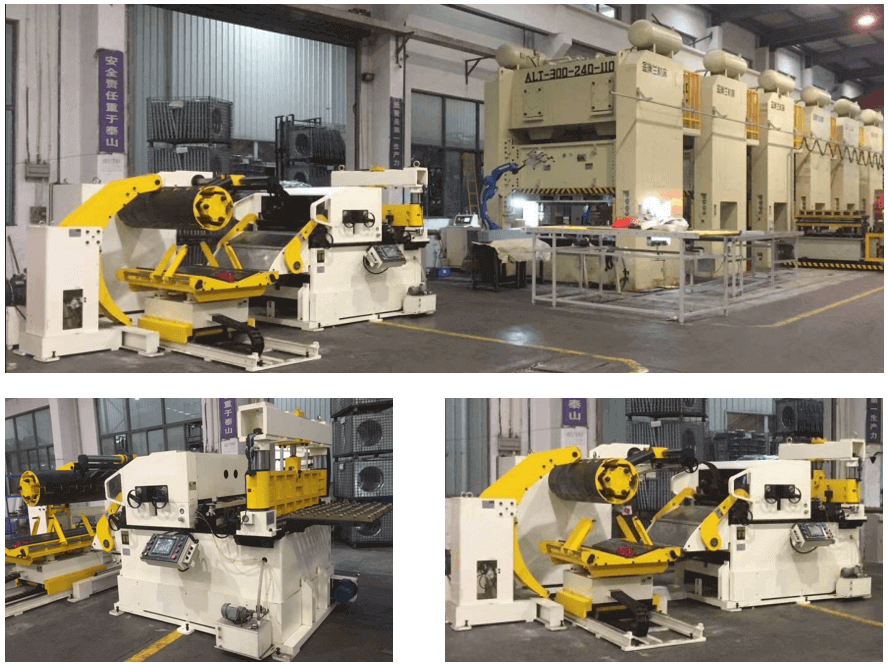

Coil Handling Equipment

Solutions

Application

About us

welcome to MAYFLAY

For consultation/feedback, please call the service hotline: +86-13692841862 Email:info@mayflay.com

What should I do if the punch feeder encounters material slippage?

The punch feeder is a commonly used material transportation machine in the industry, and it will encounter some problems in daily use, such as the material slippage of the punch feeder. Material slippage will cause a series of problems such as the material not being delivered to the position, the position is inaccurate, and the molded parts are crushed and unqualified. It is a more serious problem. How to deal with the phenomenon of material slippage encountered by the punch feeder? Let's take a look.

The first thing we have to do is to find the cause of the problem, check the cylinder management problem of the pneumatic device of the feeder, when the air pressure is not enough or the air pipe is not enough, the pressure is small, then the pressure spring is not enough when the material is clamped.

If the material is too thick, it is easy to slip the material if it is not clamped tightly. At this time, it is necessary to connect another air pipe to the air cylinder on the solenoid valve, so that the air cylinder will have thrust, so that the rollers on the feeder will be clamped tighter, so as not to It will slip, which can also be achieved by increasing the intake air pressure and increasing the cylinder pressure.

2, check whether the power spring of the feeding leveling roller is qualified and whether the rebound force can meet the requirements. If it does not meet the requirements, a new spring needs to be replaced to increase the pressure.

3. When the feeding speed of the feeder can be met, shorten the distance between the feeder and the leveler or the material rack as much as possible to reduce the waiting area, so that the weight of the material in the waiting area will be reduced, thereby reducing the feeder The load prevents the automatic punch feeder from slipping due to the excessive weight of the material in the waiting area.

If the manufacturer encounters similar problems during actual operation, please solve them in time. If the above methods cannot solve the related problems, please contact relevant professionals for help.