Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Surface Treatment Equipment

Coil Forming & Handling Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

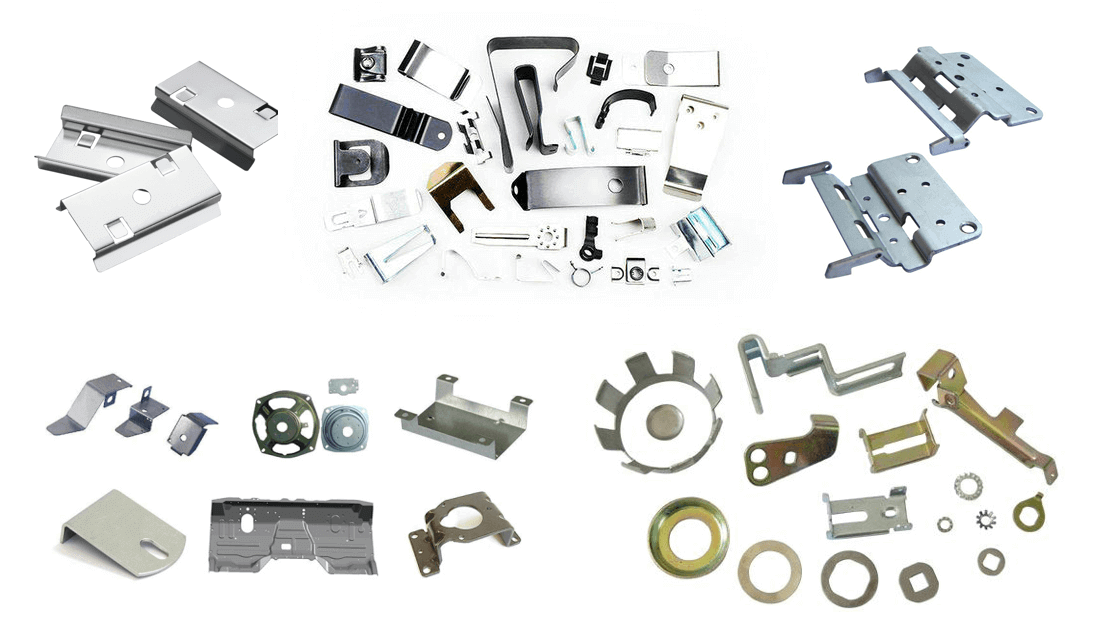

Stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping press, blanking, embossing, bending, flanging, and coining. This could be a single stage operation where every stroke of the press produce the desired form on the sheet metal part, or could occur through a series of stages. The process is usually carried out on sheet metal.

Metal sheet press feed line is a metal forming process widely used to produce parts for various industries, such as automotive stamping, electronics stamping and appliances stamping and etc.

Mechanical Power Press Machine drives the flywheel by motor, drives the crankshaft connecting rod mechanism by clutch and transmission gear to move the slider up and down, and drives the tensile mold to shape the steel plate.And the power press has two sliders, divided into sliding block inside and outside the slider, within the slider drive mould punch or die, outside the pressure of the slider to drive mould to coil, pressure rim first action during tensile steel edge, inner sliding block action stretch again.

Mechanical Power Press Machine is used for blanking, punching, bending and forming of small and medium-sized single-engined thin steel plates and high-speed progressive die parts. It is characterized by high-precision, high-yield and high-stability continuous stamping operations.

With high rigidity design in machine frame, high precision power press body is welded of quality steel sheet and treated by tension elimination, improve stability and reliability of precison of the machine.

Adjustable stroke of slide in 8 gears, to meet the punch processing for various dies.

Functions of the power press machine:

1. Keep the transmission center and machine center in uniformity, guarantee the precision of pressing.

2. In order to guarantee the machine running in stable and smooth, adopts the design of symmetrical boards with balancer.

3. The precision of mold adjusting up to 0.1mm, it's safty, reliable and convenient to adjust it.

4. Crank,gear and connect bar are oxidized hardening and milled, having super comprehensive mechanical performance and durable function.

5. Used reliable high sensitive clutch/brake and international up-to-date twin electromagnetic valve, overloading protector can guarantee the precision of slider running and stop and safe production of the machine.

6. Reasonable structural design, is benefit for automative production and reduce cost,improve efficiency.

7. Advanced design principle, low noise, low consumption, low cost, save energy.

High precision power press machine is suitable for all kinds of metal sheet stamping, including the hardware parts, home appliances, furniture hardware, motorcycle accessories, mobile phone accessories, computer accessories and so on.

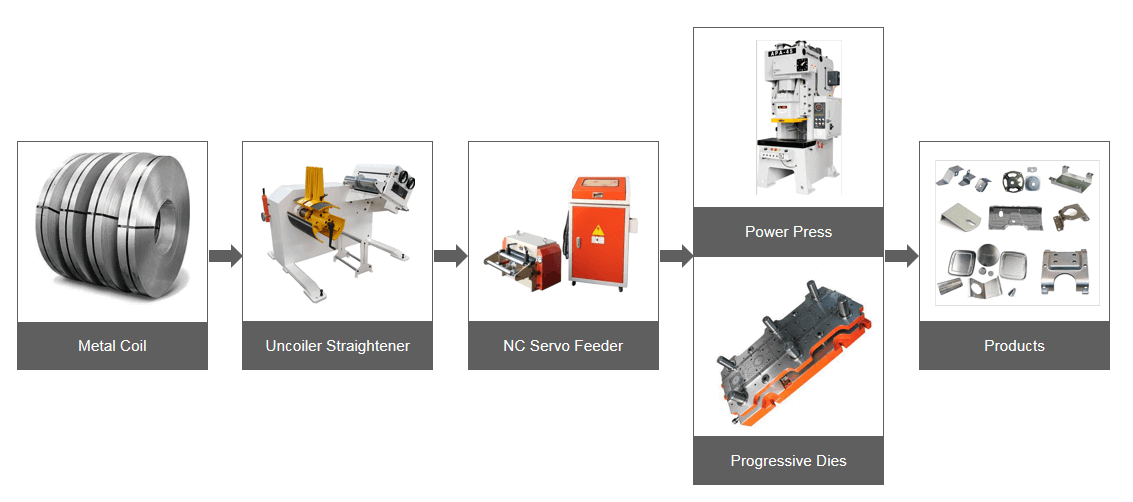

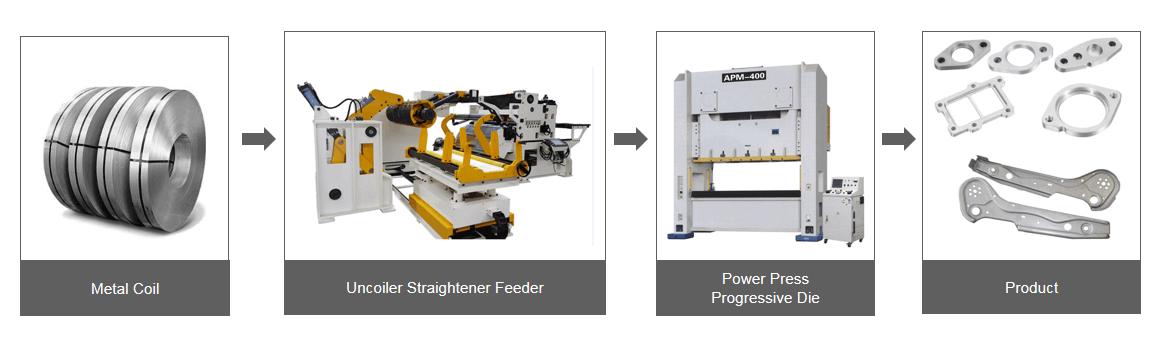

The configuration of metal sheet stamping line.

Step-1: Uncoiler straightener machine, Loading coil and uncoilling coil and level the strips.

Step-2: Nc Servo Feeder machine, Feed coil to press machine.

Step-3: Power press machine with the moulds,pressing to the end product.

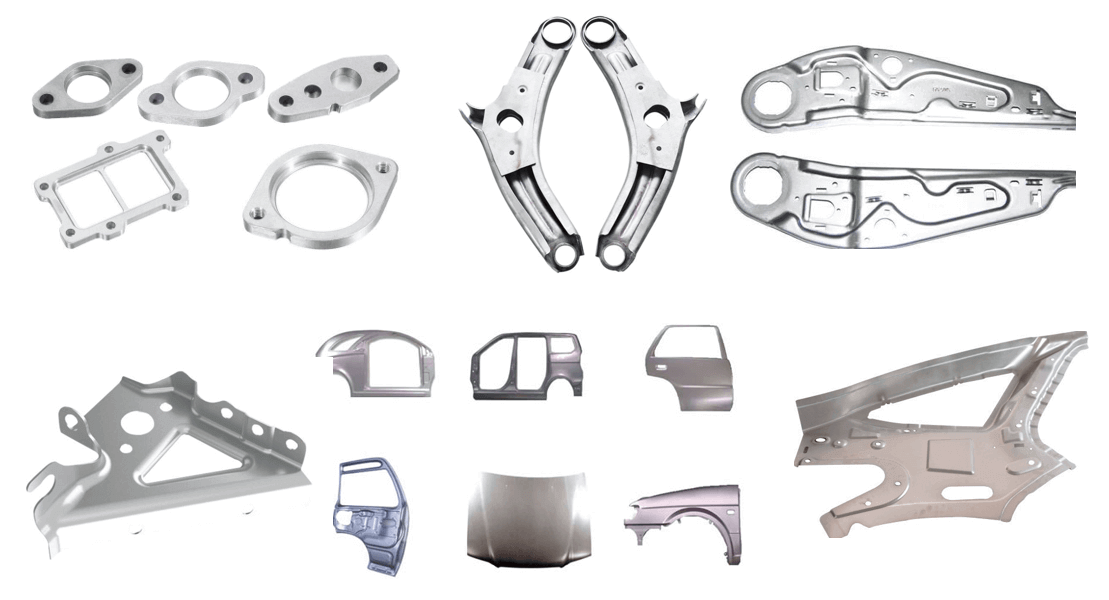

High precision power press machine is suitable for all kinds of auto parts stamping, Air conditioning parts stamping, Radiator parts stamping

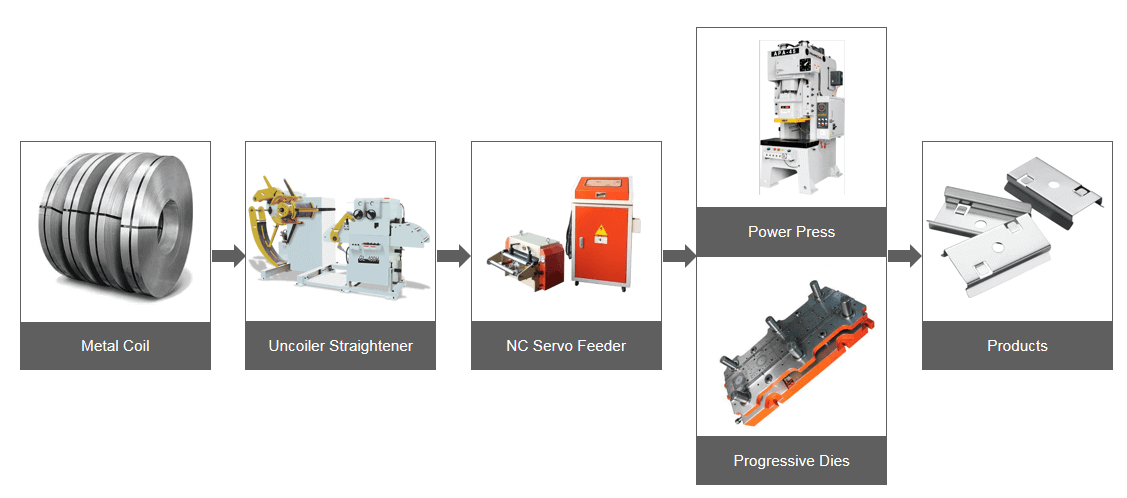

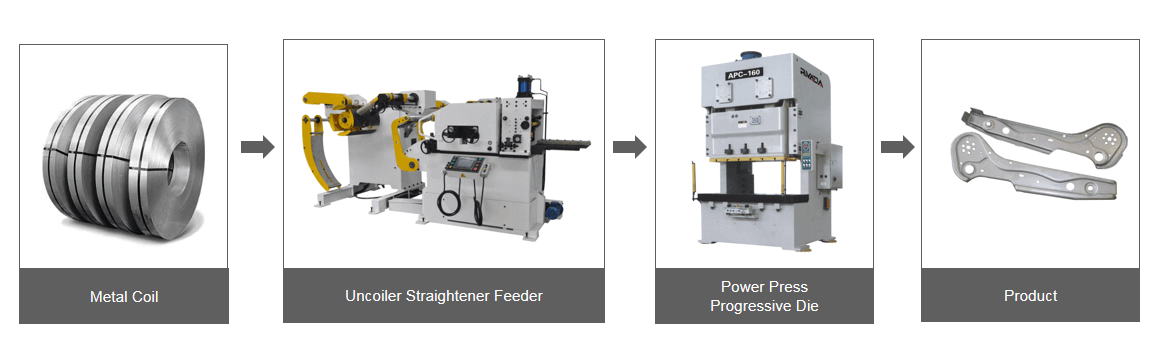

The configuration of auto stamping line.

Step-1: Compact coil feed line, Loading coil, uncoilling coil and level and feeding the strips into power press machine and die.

Step-2: Power press machine with the progressive die,pressing to the end product.

Model | APA-15B | APA-25B | APA-35B | APA-45B | APA-60B | APA-110B | |||||

Type | V | V | H | V | H | V | H | V | H | V | H |

Capacity(ton) | 15 | 25 | 35 | 45 | 60 | 110 | |||||

Rated Tonnage point (mm) | 1 | 3.2 | 1.6 | 3.2 | 1.6 | 3.2 | 1.6 | 4 | 2 | 6 | 3 |

Stroke per minute(spm) | 120-180 | 60-140 | 130-200 | 40-120 | 110-180 | 40-100 | 110-150 | 35~90 | 80~120 | 35~60 | 60~90 |

Stable speed(spm) | 130 | 110 | 85 | 75 | 65 | 50 | |||||

Stroke(mm) | 60 | 70 | 30 | 70 | 40 | 80 | 50 | 120 | 60 | 180 | 80 |

Die height(mm) | 200 | 195 | 215 | 220 | 235 | 250 | 265 | 310 | 340 | 360 | 410 |

Slide adjustment(mm) | 50 | 50 | 55 | 60 | 75 | 80 | |||||

Slide area(mm) | 300*230*50 | 300*230*50 | 360*250*50 | 400*300*60 | 500*360*70 | 650*470*80 | |||||

Bolster area(mm) | 680*300*70 | 680*300*70 | 800*400*70 | 850*440*80 | 900*500*80 | 1150*600*110 | |||||

Shank hole(mm) | Ф38.1 | Ф38.1 | Ф38.1 | Ф38.1 | Ф50 | Ф50 | |||||

Main motor(KW*P) | 2.2*6 | VS3.7*4 | VS3.7*4 | VS 5.5*4 | VS 5.5*4 | VS 11*4 | |||||

Slide adjusting device | Manual | ||||||||||

Air pressure(kg/cm2) | 6 | ||||||||||

Press precision | GB/JIS first class | ||||||||||

Press dimension | 1236*820*1920 | 1280*850*2200 | 1600*950*2500 | 1600*1000*2800 | 1900*1300*3200 | ||||||

Press weight(ton) | 1.8 | 2.1 | 3 | 3.8 | 5.6 | 9.6 | |||||

Die cushion capacity(ton) | - | - | 2.3 | 2.3 | 3.6 | 6.3 | |||||

Stroke of die cushion(mm) | - | - | 50 | 50 | 70 | 80 | |||||

Effective area of die cushion(mm) | - | - | 300*230 | 300*230 | 350*300 | 500*350 | |||||

Model | APA-160B | APA-200B | APA-260B | |||

Type | V | H | V | H | V | H |

Capacity(ton) | 160 | 200 | 260 | |||

Rated Tonnage point (mm) | 6 | 3 | 6 | 3 | 7 | 3.5 |

Stroke per minute(spm) | 20~50 | 40~70 | 20-50 | 50-70 | 20-40 | 40-50 |

Stable speed(spm) | 35 | 35 | 30 | |||

Stroke(mm) | 200 | 90 | 200 | 100 | 250 | 150 |

Die height(mm) | 460 | 510 | 460 | 510 | 500 | 550 |

Slide adjustment(mm) | 100 | 110 | 120 | |||

Slide area(mm) | 700 *550*90 | 850*630*90 | 950*700*100 | |||

Bolster area(mm) | 1250*800*140 | 1400*820*160 | 1500*840*180 | |||

Shank hole(mm) | Ф65 | Ф65 | Ф65 | |||

Main motor(KW*P) | VS 15*4 | VS18.5*4 | VS22*4 | |||

Slide adjusting device | Electrical driving | |||||

Air pressure(kg/cm2) | 6 | |||||

Press precision | GB/JIS first class | |||||

Press dimension | 2300*1400*3800 | 2615*1690*4075 | 2780*1850*4470 | |||

Press weight(ton) | 16 | 23 | 32 | |||

Die cushion capacity(ton) | 10 | 14 | 14 | |||

Stroke of die cushion(mm) | 80 | 100 | 100 | |||

Effective area of die cushion(mm) | 650*420 | 710*480 | 810*480 | |||