Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Surface Treatment Equipment

Coil Forming & Handling Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

As we all know, the routine maintenance affects the shot blasting machine spanlife so much, even the same machine, if it is well maintained, the service life will be many years longer than the bad maintained situation. So what should we do for routine maintenance of the shot blasting machine?

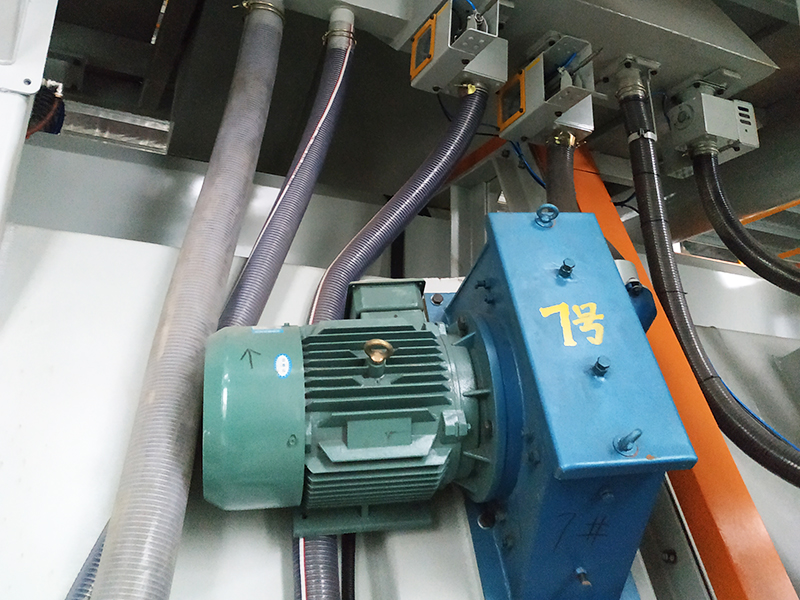

1.Are the fixing bolts on the shot blasting wheel loose?

2.Whether the internal parts are worn?

3.Does the dust pipe leak air?

4.Is there any sediment on the blasting machine?

5.Whether each switch and indicator light are normal?

This is a giant and long catenary through shot blasting machine in our client's workshop. It consists of the work piece inlet & outlet chamber and the blasting chamber with 16pcs high-quality casted blast wheels placed at two sides of the blasting chamber. Our specially-designed wet Venturi dust collector was installed to have high efficiency of dedusting. The length of the hanging chain and the number of the hangers can be customized according to customer's workpiece productivity and efficiency requirements.

Usually, continuous hanging chain shot blasting machine needs a pit to have the lower part of the machine installed in the pit to save room but this will be done according to the local government policy of building a workshop.

Economic style solution with powerful capacity of cleaning thoroughly every side of work pieces that are suitable for tumbling. It is an ideal option for blasting and cleaning work pieces in batches to have optimum blasting results on small delicate metallic parts, heavy castings, partially covered with sand or scale.

Work pieces are loaded into the blasting chamber manually or automatically with loading & unloading system. In the process of blasting, work pieces are continuously cascading and tumbling over each other, resulting in all-around blasting coverage with high efficiency. Work pieces touch and contact each other during the tumbling make it even easier for blasting process.

Automatic loading and unloading system makes Mayflay tumble belt shot blasting machine a typical & optimized choice to have reliable quality, extremely long lifespan, high efficiency of blasting and save cost of labor.

Mayflay manufactures single-turntable and double-turntable version rotary table shot blasting machine, and both work with the main turntable. Hangers can be equipped on both single-turntable and double-turntable version to have easier and more thorough shot blasting work for hanging work pieces.

Multiple working stations can be designed on the main turntable to allow work pieces loading when at the same time other work pieces are in the blasting process to save time of working. This machine is an ideal solution for symmetric parts and the turntable can be programmed to stay at specific position to work with specific blasting wheel to have thorough surface cleaning of dissymmetric parts.

Mayflay rotary table shot blasting machine can handle work piece at max. weight 50KG for double-turntable version and up to 2000KG for single-turntable version and the maximum weight can be even higher. Work pieces are either loaded as a large single component for processing or hung on specific hanger on the turntable and rotated to the working stations for blasting process. It is usually used for medium casting and forgings, valves and petroleum drill etc.

Mayflay wire mesh belt shot blasting machines are specially designed for constant and continuous blasting of de-scaling, de-sanding, cleaning and pre-treatment for different type of medium & small work pieces with great processing capacity. It is especially suitable for work pieces in wide and flat shape. No crush among work pieces during blasting, great blasting capacity, high efficiency, guaranteed sealing system, compact design and easy loading and unloading, all these features make our wire mesh belt shot blasting machine an ideal option for many fields, such as automotive parts, forgings, castings, ship parts manufacturing, aerospace industry, aluminum alloy parts and machinery industry etc.

Wire mesh belt works as the carrier of work pieces in the wire mesh belt shot blasting machine and is available in two types: steel wire mesh belt & wear-resisting rubber wire mesh belt.

Our Advantages

*Top quality

The wire mesh belt, made of Mn 13 steel materials, is highly durable and wear-resisting and driven steadily and stably by the chain and chain wheel. The wire mesh belt transport system ensures efficient shot blasting on parts/components, including sand and die castings, profiled and flame cut and car body parts as well as machined work pieces, which may be too small for a roller conveyor shot blasting machine. Work pieces can be placed on the wire mesh side by side for constant & continuous blasting process to reach high efficiency, save abrasives and have with reliable performance of cleaning & dedusting.

Blasting machine body: 6-10mm thickness Manganese 13 steel plates well-welded in one piece and Manganese 13 steel protective boards, offering excellent wear resistance and protection from even the most aggressive blast media

*Smart designs

The position of the high-performance blasting wheels, ideally set at a vertical as well as at a horizontal angle on the blasting chamber, ensures that complicated surface areas of work pieces are fully reached by the blasting shots.

Ultimately compact design for easy operation and wide range of options of models to adapt to diversified production efficiencies and sizes of work pieces.

*All-around shot blasting machine

Mayflay wire mesh belt blasting machines are the best solutions for all-around continuous blast cleaning of flat, wide and complex shaped work pieces. This high flexible machine guarantees a high operational efficiency for a wide range of shot blasting applications, especially for deburring, blast cleaning, surface roughening, de-scaling and de-rusting.

*High-end technology applied

In front of the blasting chamber inlet, optical grating detecting device is installed to transmits time-lapse signal to the PLC as soon as the work piece goes into the blasting chamber to start the blasting process.

*Mayflay technique of sealing system

Blasting sealing: rubber segments are equipped at the roller conveyor inlet & outlet and the blasting chamber to keep the machine nearly 100% tight and prevent accidents of shot spillage.

*All-in-one control & operation center

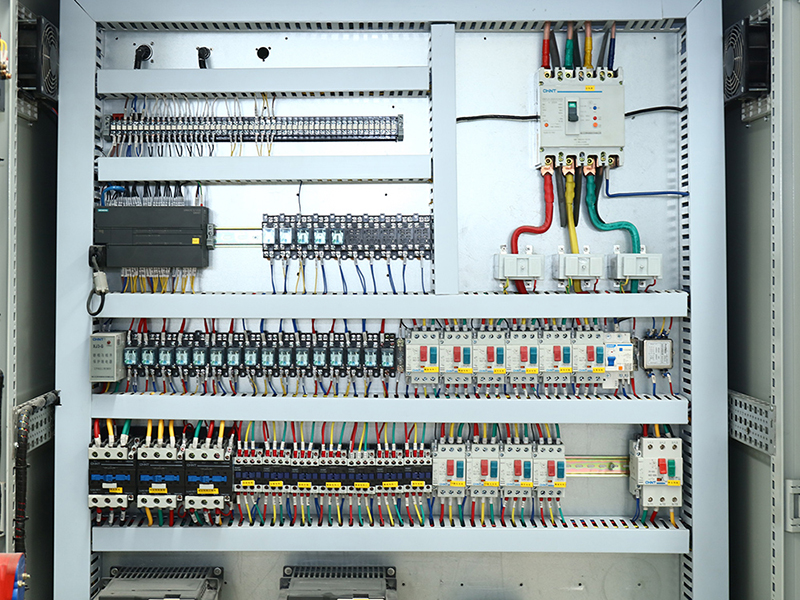

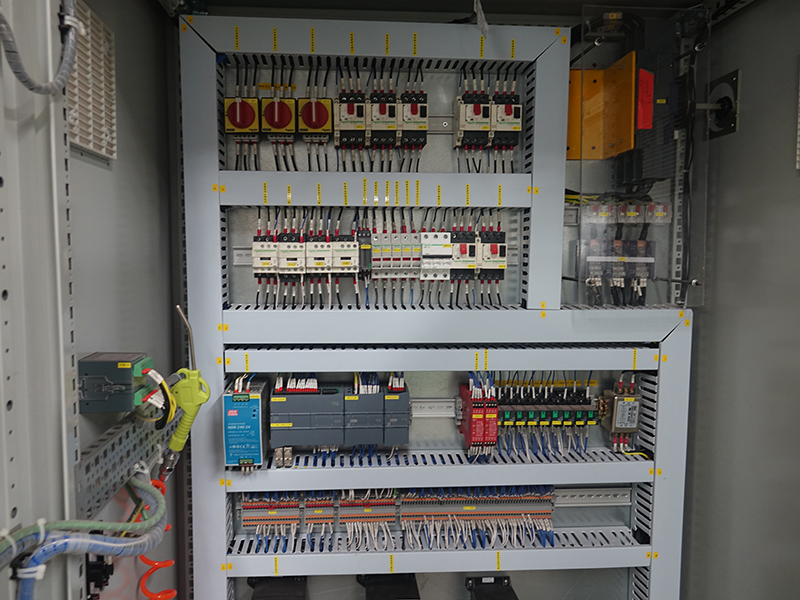

PLC control, all process parameters of work pieces blasting can be configured and saved in PLC control unit, in the result that repeat input, repeat pushing different buttons are completely unnecessary. This means, much shorter time of parameter configuration, much less working hours of operator and high efficiency.

Smart communication with built-in 3D guiding technology UI and 7 Inch colorful touch screen for safe operation, easy maintenance.

*Care about environment

Great importance is attached by Mayflay to environment protection: noise and dust emission. We adopt high-end methods to reduce noise to 85DB and dust emission concentration to less than 50mg/m3 (these results can be even better with higher standard of configurations).

Range of applications

This is highly flexible system that can be applied in many applications such as de-scaling, de-sanding of forgings, castings, stamping parts, aluminum parts and heat-treated parts, rust removal, sand removal of iron, steel and metal castings, in fields of automotive vehicle, aerospace, railway and machinery etc. It is especially suitable for work pieces in wide and flat shape and pipes, wires and work pieces that are not suitable for tumbling.

Mayflay manufactures single-turntable and double-turntable version rotary table shot blasting machine, and both work with the main turntable. Hangers can be equipped on both single-turntable and double-turntable version to have easier and more thorough shot blasting work for hanging work pieces.

Multiple working stations can be designed on the main turntable to allow work pieces loading when at the same time other work pieces are in the blasting process to save time of working. This machine is an ideal solution for symmetric parts and the turntable can be programmed to stay at specific position to work with specific blasting wheel to have thorough surface cleaning of dissymmetric parts.

Mayflay rotary table shot blasting machine can handle work piece at max. weight 50KG for double-turntable version and up to 2000KG for single-turntable version and the maximum weight can be even higher. Work pieces are either loaded as a large single component for processing or hung on specific hanger on the turntable and rotated to the working stations for blasting process. It is usually used for medium casting and forgings, valves and petroleum drill etc.

Our Advantages

l Options of turntable & Compact design

Single-turntable version and double-turntable version are available for different shot blasting tasks and work pieces.

Ultimately compact and smart design and small floor space occupation.

l All-around capability

A wide variety of different work pieces can be processed on the turntable, from sturdy components in different shapes and sizes to very delicate, fragile parts. Easy integration into complete manufacturing lines and the possibility of automated part loading and unloading make the Mayflay rotary table shot blasting machine a truly all-around shot blasting system.

l Time-saving and smart blasting

Multiple working stations can be designed on the main turntable to allow work pieces loading when at the same time other work pieces are in the blasting process to save time of working. The turntable can be programmed to stay at specific position to work with specific blasting wheel to have thorough surface cleaning of dissymmetric parts.

l Reliable quality & customizable size

Shot blasting chamber is completely engineered of manganese steel plates with thickness between 6 and 10 mm and welded in one piece, making the machines extremely tight and sturdy. For optimum wear protection, the area exposed to the blast stream is lined with replaceable protective manganese steel plates. These overlapping liners are not bolted on but hung with a special system.

Different design configurations and capacity sizes are available for low and high work piece requirements. Size, number and power of blasting wheel vary considerably depending on work pieces as well as the expected result and efficiency.

l Programmable Logic Controller

Much shorter time of parameter configuration, much less working hours of operator and high efficiency because all process parameters of work pieces blasting can be configured and saved in PLC control unit without unnecessary repeat input & repeat pressing different buttons.

Smart communication with built-in 3D guiding technology UI and 7 Inch colorful touch screen for safe operation, easy maintenance.

l Environment protection

We adopt high-end methods to reduce noise to 85DB and dust emission concentration to less than 50mg/m3 (these results can be even better with higher standard of configurations).

Range of application

The Mayflay rotary table shot blasting machines are highly flexible systems that can be applied in many applications such as de-scaling, de-sanding, rust removal, paint stripping for flammable and explosive parts, perforated parts, gears, medium casting and forgings, valves and petroleum drill etc.

1.Removal of Corrosion:

This is the most preferred technique for removing all forms of rust and corrosive materials for metal and steel surfaces without reducing the strength of the product and leaving its base unaffected. Typical builds of corrosive that develop on the surfaces are:

1.Rust

2.Chemical Stains

3.Mill Scale

4.Faded or Chipped Paint

5.Heat Treatment Scale

2.Preparation of Surface:

This method blasting is by far the most effective and most efficient process for preparing a metal surface before the painting or coating process is done. It provides high blast pattern accuracy, with an extremely powerful bond between blasted surface and the protective coating. The technique helps in revealing any type of defects and errors. It also increases the lifespan and the endurance of any future coating.

3.Environmental Reasons:

This blasting technique is one of the only few options that provide environment friendly options for the removal of corrosion and the preparation of surface:

1. The process involves the use of only abrasion to clean the surface of the metal products

2. No chemicals are used during the entire process.

3. Acids too are not used at any time in the entire process.

4. The only required clean up is of the physical pellets.

5. All the blasted steel or dust of medias is blown away by a powerful vacuum and dust collecting system.

6. The process also provides the freedom and convenience of recycling the materials used in the process.

Mayflay catenary through shot blasting machines are specially designed for medium and small work piece surface cleaning in large quantity. It adopts single-strand closed-loop transport system. Conveying hooks are loaded with work pieces before moving into the blasting chamber. Work pieces go into the chamber for blasting process at constant speed and frequency. Flexible way and continuous blasting is time & cost effective and this single-strand closed-loop transport system is the best solution to have joint work of transporting and blasting and to be integrated with painting/oil injection line perfectly.

The raw work pieces can either be loaded as a large single component for processing or hung on specific hanger.

Our Advantages

l Space-saving, cost-saving, time-saving

Catenary through shot blasting machine is usually giant but we use ultimately compact design to save space.

Constant & continuous blasting process with high efficiency saves abrasive costs with reliable performance of cleaning and dedusting.

Workable integration into existing production line and joint work with painting line saves production time.

l Reliable quality & long lifespan

Shot blasting chamber is completely engineered of manganese steel plates with thickness between 6 and 10 mm. The blast chamber up to a certain models is welded in one piece, making the machines extremely tight and sturdy. For optimum wear protection, the area exposed to the blast stream is lined with replaceable protective plates that are constructed in manganese steel. These overlapping liners are not bolted on but hung with a special system.

l Customizable machine size

This type of machine is available in more design configurations and capacity sizes to adapt to low or high production parts requirements. The machine size, the number and power of the wheel blasters vary considerably depending on the different work pieces as well as expectations of result and efficiency.

l High-efficiency transport system

Single-strand closed-loop transport system. Work pieces go into the chamber for blasting process at constant speed and frequency. Flexible way and continuous blasting is time & cost effective and this is the best solution to have joint work of transporting and blasting and to be integrated with painting/oil injection line perfectly.

l Sealing system

Blasting sealing: rubber segments are equipped at the roller conveyor inlet & outlet and the blasting chamber to keep the machine nearly 100% tight and prevent accidents of shot spillage.

l Smart PLC

All process parameters of work pieces blasting can be configured and saved in PLC control unit, in the result that repeat input, repeat pushing different buttons are completely unnecessary. This means, much shorter time of parameter configuration, much less working hours of operator and high efficiency.

Smart communication with built-in 3D guiding technology UI and 7 Inch colorful touch screen for safe operation, easy maintenance.

l Environment protection

Great importance is attached by Mayflay to environment protection: noise and dust emission. We adopt high-end methods to reduce noise to 85DB and dust emission concentration to less than 50mg/m3 (these results can be even better with higher standard of configurations).

l Thorough blasting effect

To achieve complete coverage, this machine is usually equipped with 8-16 blast wheels. With this number of blast wheels, every work piece in the blasting chamber will be thoroughly treated from each side and this keeps high efficiency on continuous coming work pieces in large quantity.