Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

Our company is well received by customers with perfect solutions, good product quality, performance, and after-sales

Steel abrasives are steel particles that are used as abrasive or peening media.They are usually available in two different shapes (shot and grit) that address different industrial applications.

Steel shot refers to spherical grains made of molten steel through an atomization ("granulation") process, available in different sizes and hardnesses.

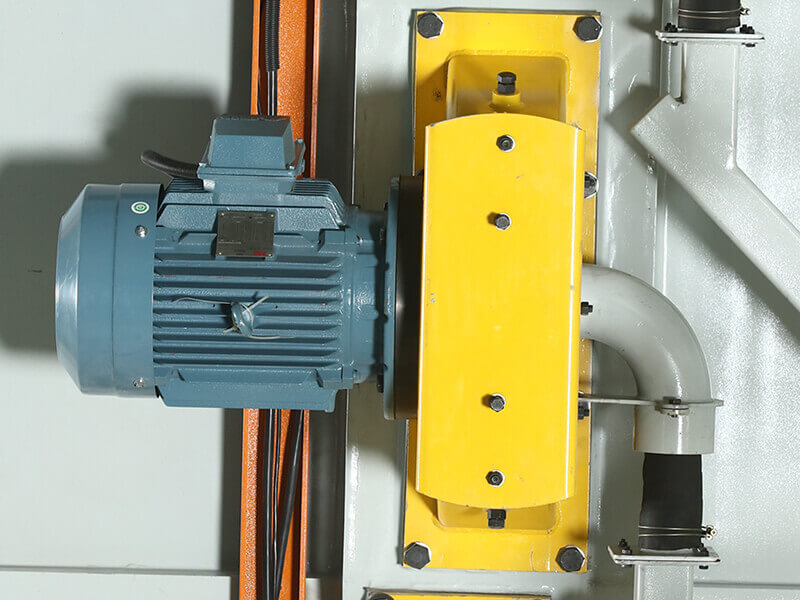

One vane wheel, 8 pieces of high-hardness and wear-resistant precision CNC machining blades, directly inserted type, installed on the vane wheel; A Control cage and impeller control the pellet throwing direction and preaccelerate the pellet feeding respectively.

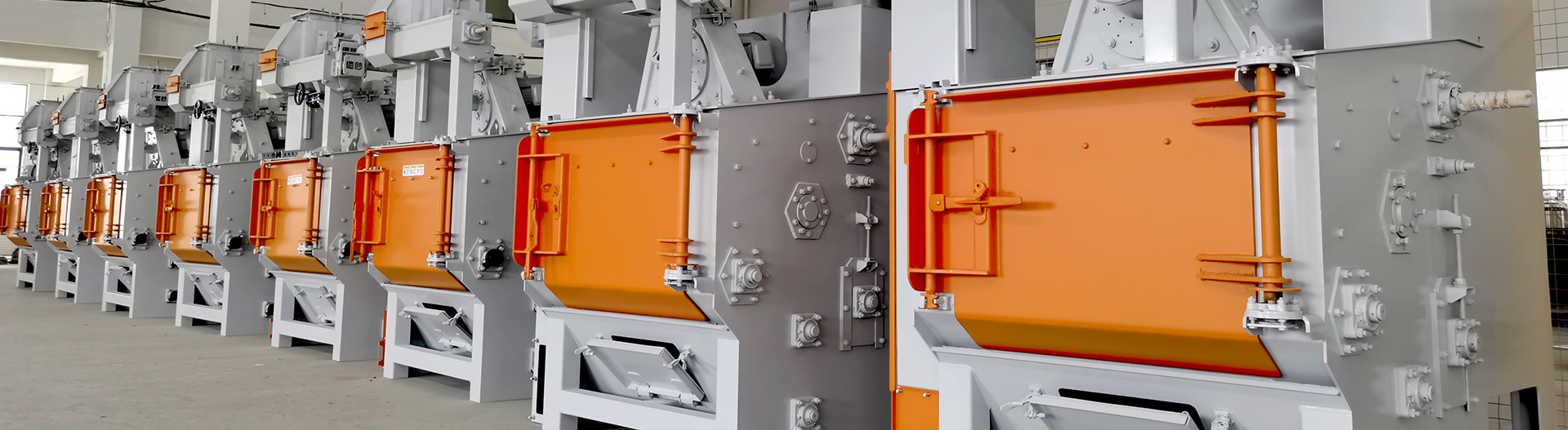

All kinds of shot blasting machines

Venturi dust collector is a device which makes dust-containing gas contact with liquid (half water), uses inertial collision of water droplets and particles and other functions to capture particles; it is composed of water storage tank, dust collection pipeline, dust chamber, dust removal fan, dust removal pump, mud removal system, dust collecting hopper, cyclone separator, maintenance platform, spray system, explosion-proof window.

A dust collector is a system used to enhance the quality of air released from industrial and commercial processes by collecting dust and other impurities from air or gas. Designed to handle high-volume dust loads, a dust collector system consists of a blower, dust filter, a filter-cleaning system, and a dust receptacle or dust removal system. It is distinguished from air purifiers, which use disposable filters to remove dust.

Sandblasting Cabinet is a kind of machine that uses compressed air as power to form a high-speed jet beam which sprays the abrasives into the surface of the workpiece to be treated at high speed. Because of the impact and cutting action of abrasives on the workpiece surface, the workpiece surface is cleaned up to a certain extent and has different roughness, so the mechanical properties and fatigue resistance of the workpiece surface are improved, and the adhesion between the workpiece and the coating is increased, the durability of the coating is prolonged, and it is also conducive to the leveling and decoration of the coating.

Sandblasting Room is ideal for the large-scale structures, widely used in blasting of hulls, stoves,boilers and wind power parts, etc.Large structures can move inside the Blast Room on work cars sliding on rails. Mainly composed with the main body of Blasting Room, Workpiece Transportation System,Sandblasting System, Abrasive recovery system, ,Dust Collecting System, Central Control System and lighting system.

Coil Spring shot peening machine is a kind of equipment for spring surface treatment. Shot blasting strengthening is a specially designed technology to improve the fatigue strength of components subjected to alternating stress. Cyclic plastic strain layer is produced on the surface of spring by the impact of high-speed steel shot flow on the spring surface, which leads to favorable changes in the microstructures of the spring surface and the introduction of residual compressive stress field into the surface. Thus, the fatigue fracture and stress corrosion fracture resistance of the spring can be improved, and the reliability and durability of the spring can be improved.

Shot peening is used to improve the fatigue strength of workpieces subjected to high stress and alternating stress. Shot peening has replaced a wide range of other time-consuming and expensive processes, enabling the design of lower cost and lighter weight parts.